Optical fiber communication is a communication mode that uses light wave as carrier and Optical fiber as transmission medium. Fiber optic communication is widely used in the communication field due to its long transmission distance, large communication capacity, high communication quality, low engineering cost, and high security and confidentiality. Optical time-domain reflectometer (OTDR) is the main instrument in optical fiber testing. It is widely used in the maintenance and construction of optical cable lines, and can measure the length of optical fiber, transmission attenuation of optical fiber, joint attenuation and fault location. OTDR has the advantages of short testing time, fast testing speed, and high testing accuracy. It uses the time-domain measurement method to transmit an optical pulse with a certain width and inject it into the measured fiber. Then, by detecting the distribution curve of Rayleigh scattering and Fresnel reflected light signal power along the time axis returned from the fiber, it can detect the length, loss and other physical properties of the measured fiber. At the same time, its powerful data analysis function can accurately locate the event points and fault points in the fiber link. At present, optical time-domain reflectometers can use wavelengths such as 850nm, 1300nm (suitable for multimode fibers), 1310nm, 1380nm, 1480nm, 1550nm, and 1625nm (suitable for single-mode fibers) for fiber optic line measurement. The focus of the measurement is to detect the fusion of fibers, the loss of joints and lines, and verify whether the distance between each fiber is correct compared to the construction.

OTDR has been throughout the whole project during the construction of optical cables, such as single panel testing, testing after the laying of optical cables, fusion testing and Acceptance testing after construction. The purpose of testing single disc optical cables is to verify the quality of factory products; The testing after construction layout is to check for any damage during the layout process and serve as a pre connection inspection; The testing during the connection is to check whether the joint meets the design requirements; The testing of the entire optical cable section after connection is to verify whether the loss of the relay section meets the design requirements and to inspect the condition of the optical cable after the completion of construction.

Below is a detailed explanation of the entire process:

1. Before laying the optical cable, a single disc test should be conducted and an initial test data ledger should be established. Due to the repeated loading and unloading of optical cables from the factory to the buyer’s unit and then to the construction site, it is difficult to ensure that the optical cables are not damaged. Therefore, the purpose of single disc testing of optical cables is to clarify the boundaries of responsibility and ensure that the cables are in good condition before construction. From the perspective of maintenance and operation, there are two purposes: one is to ensure that the optical cable is not damaged before construction, and the other is to determine the length and end type of the optical cable through initial test data. By using these data, the order of optical cable laying and the position of optical cable joints can be reasonably arranged to facilitate the construction and connection of the optical cable, while also ensuring the quality of optical cable construction.

- After the optical cable is laid out, it must also be retested before connection. This is because with the advancement of technology, the welding quality of fiber optic fusion splicers has significantly improved, making the loss of fusion joints no longer the main factor in fiber optic line loss. Due to the small fusion loss, the change in optical power after the optical signal passes through this point is not significant. When using OTDR testing, it is difficult to determine, and it is also difficult to find the fusion point in the testing curve of the optical fiber link, which will cause many inconvenience in future operation and maintenance. So retesting before splicing can prevent such problems from occurring and also verify whether the optical cable has been damaged during laying. The pre connection testing is the same as the general OTDR testing method, except that before the fiber optic cable is connected, the tested fiber optic cable length and loss data are stored, and a database of line segment length and loss is established as an important reference for future line maintenance. It can also be used to verify whether there are any deviations in construction based on design approval.

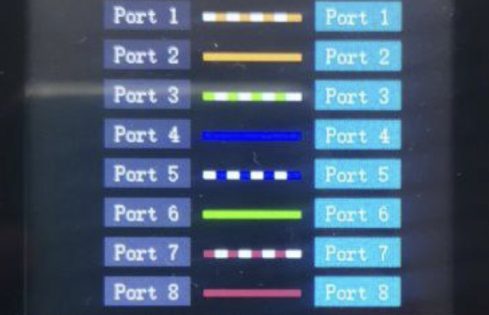

- After the fiber optic cable is fused, it needs to be tested again using OTDR. This test has two purposes: 1) to test whether the fusion loss of the fusion point exceeds the design requirements. Once a superscript point is found, it can be re fused in a timely manner to ensure that the transmission loss of the entire relay section meets the design requirements. 2) to confirm whether the core wire of the fiber optic cable is connected incorrectly through testing, as it is difficult to ensure that hundreds of fiber optic cables are not connected incorrectly. At the same time, it is necessary to confirm after closing the joint box.

4. After the completion of the fiber optic cable project, the final testing of the line is also required. The post construction test mainly refers to the self test, self inspection and self inspection of the optical cable line. The test data can be used as a reference for subsequent acceptance. The acceptance party’s test mainly refers to the Acceptance testing of the length of the optical cable line, the loss of the trunk section and the joint loss according to the design requirements. The test data is used to establish a database as an important reference for future operation and maintenance. It is also handed over to the operation unit as part of the project completion data.

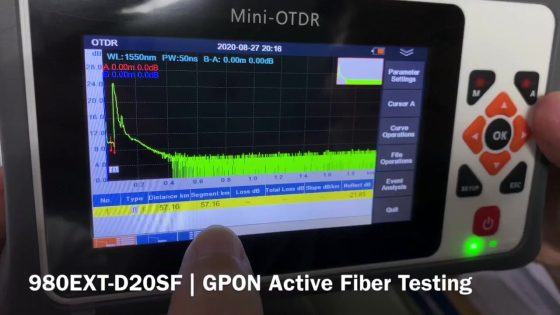

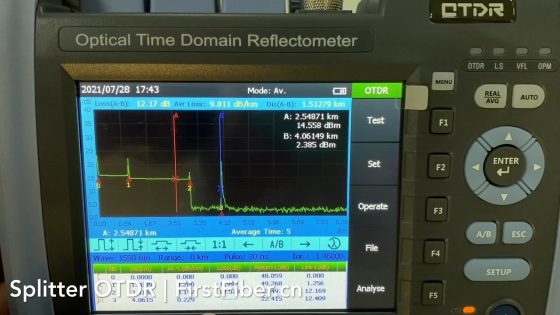

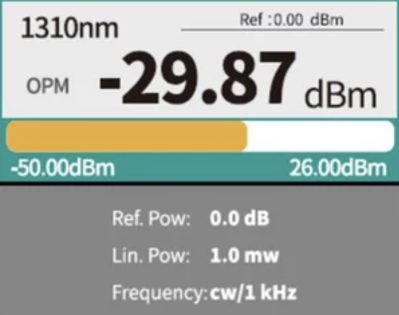

The purpose of using OTDR to test fiber optic circuits is to obtain information on the length, line loss, fusion loss, fusion point, and fault location of the fiber optic. For general testing, the automatic testing function of OTDR can meet the requirements, but in some cases, automatic testing may not provide satisfactory results. For example, in short distance (within a few tens of meters) and ultra long distance testing, the determination and positioning of event points may not be accurate. Places without event points may be misjudged as having event points, and some expected event points may also be missed. In this case, It is best to use manual testing mode.

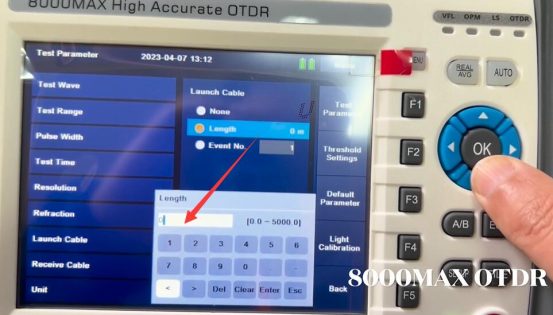

The manual testing mode requires the operator to select appropriate testing parameters based on the distance of the tested fiber, such as testing range, pulse width, attenuation, and average frequency. Using appropriate testing parameters will result in the best test results. When selecting the testing range, it must be noted that the selected testing range should be greater than the length of the tested optical fiber, preferably twice the length of the tested optical fiber. This is to prevent the impact of secondary reflection at the end of the optical fiber (when the testing range is less than twice the length of the tested optical fiber, the secondary reflection peak at the end of the optical fiber may fall on the flat testing curve, causing the commonly known “ghost” and causing the illusion of a faulty point in the optical fiber link). But this does not mean that the test range is less than twice the length of the tested optical fiber and cannot be tested. Firstly, the appearance of “ghost” depends on the reflection strength at the end of the optical fiber. If the reflection is very weak, the probability of “ghost” appearing is very small; Secondly, once a “ghost” appears, how to judge and avoid it? Experienced operators will enlarge the testing range before testing, or bend the end of the optical fiber. If the reflection peak on the curve disappears, it indicates that the previously generated reflection peak is a “ghost”.

The choice of testing pulse width also depends on the length of the tested optical fiber. When testing long-distance optical fibers, try to choose a larger pulse width; If you want to test short distance optical fibers (such as distances less than 1km), it is best to choose the minimum pulse width. Due to the fact that the size of the pulse width determines the spatial resolution, when testing, choosing a small pulse width as much as possible under the allowable signal-to-noise ratio of the curve will yield more accurate results for event points.

In the testing parameters of OTDR, there is also the setting of the average number of times. Some OTDR sets the average time with the same meaning, both of which are used to suppress noise in the curve as much as possible and make the testing curve smoother. The setting of the average frequency (or average time) should be flexibly controlled according to the specific situation. Generally speaking, after an average processing of a certain number of times (such as 300 times or 3 minutes), the effect is no longer significant.

During the construction of optical cables, attention should be paid to maintenance and upkeep when using OTDR:

(1) Keep the OTDR optical output head clean; Before each test, clean the end face of the tested optical fiber.

(2) The optical output head of OTDR is generally FC/PC type or FC/APC type. It should be noted that the joint type of the tested fiber should match the optical output head of OTDR.

(3) Do not connect the tested fiber in the real-time testing state of OTDR.

(4) To extend the service life of the battery inside the machine, it is best to fully charge the OTDR battery after construction to ensure normal use during the next construction. When not in use for a long time, it is generally necessary to charge and discharge at least once every 3 months.

With the progress of science and technology, the application fields of fiber optic communication are becoming increasingly widespread. The optical time domain reflectometer plays a very important role in the construction, maintenance and testing of optical cable engineering, and is an important guarantee for the construction of optical cable engineering.

Comments are closed.